Anti Caking Agent

Price 12 INR/ Kilograms

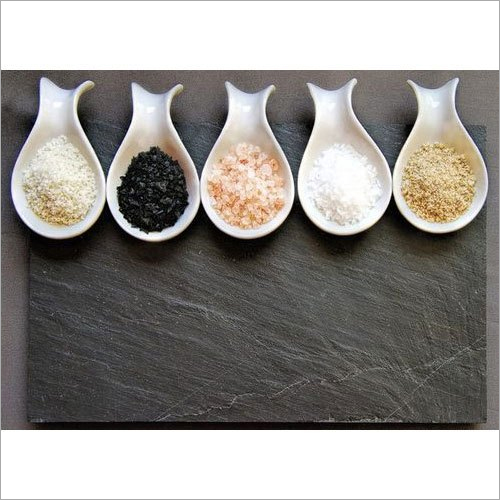

Anti Caking Agent Specification

- Application

- Food

- Shape

- Crystal

- Rubbing Resistance

- Dry

- Size

- Powder

- CAS No

- 7631-86-9

- Type

- Basic Dye

- Usage

- Food Dyestuffs

- Physical Form

- Powder

Anti Caking Agent Trade Information

- Minimum Order Quantity

- 100 Kilograms

- FOB Port

- Vadodara

- Payment Terms

- Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 1000 Kilograms Per Day

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- HDPE Bag

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India, Andaman and Nicobar Islands, South India, Arunachal Pradesh, Delhi, Goa, Meghalaya, Rajasthan, Daman and Diu, North India, Jharkhand, Madhya Pradesh, Bihar, Assam, Central India, Himachal Pradesh, Chhattisgarh, Tripura, Telangana, Punjab, Odisha, , East India, Kerala, West India, Lakshadweep, Gujarat, Tamil Nadu, Karnataka, Uttarakhand, West Bengal, Dadra and Nagar Haveli, Maharashtra, Uttar Pradesh, Mizoram, Andhra Pradesh, Chandigarh, Nagaland, Haryana, Sikkim, Manipur, Pondicherry, Jammu and Kashmir

About Anti Caking Agent

Due to our years of experience in this field, we are engrossed in providing the best quality Anti Caking Agent. Our offered item is widely used in flavors and sauces, for example, salt, flavors, and bean stew powder to keep them dry. It is an added substance put in powdered or granulated materials, for example, table salt or candy stores to forestall the development of protuberances. This Anti Caking Agent is offered by us at cost effective price to our valuable clients within the promised time frame.

Why Use an Anti Caking Agent with Rubbing Resistance?

Anti caking agents with rubbing resistance are vital for maintaining the texture and flow of powdered products, particularly under transportation stress. Their unique property of rubbing resistance ensures that the product does not form lumps, even when subjected to friction, helping preserve product quality from manufacturing facility to end user.

Applications Across Food and Fertilizer Industries

Our crystalline anti caking agent is formulated for use in both food and fertilizer industries. In food, it ensures seasonings, spices, and baking goods remain free-flowing and easy to use. For fertilizers, it prevents clumping during storage and transport, providing practical benefits to agricultural operations.

FAQs of Anti Caking Agent:

Q: How is the anti caking agent with rubbing resistance applied in food and fertilizer industries?

A: The agent is evenly mixed into powdered or granulated products during processing. In the food industry, it is incorporated into seasonings, dry mixes, and other products to prevent clumping. In fertilizer manufacturing, it is similarly blended to ensure the final product remains loose and easily spreadable.Q: What benefits does rubbing resistance provide to anti caking agents?

A: Rubbing resistance prevents the anti caking agent from losing its effectiveness when subjected to friction, such as during handling, packing, or transit. This feature ensures the product maintains its free-flowing characteristics and resists clumping for a longer period.Q: When should I add the anti caking agent during my production process?

A: It is best to introduce the anti caking agent during the final stages of mixing or right before packaging to evenly distribute the agent and maximize its effect, ensuring consistent performance throughout the product batch.Q: Where can this anti caking agent be sourced in India?

A: We are a prominent exporter, importer, manufacturer, supplier, trader, and wholesaler of anti caking agents based in India, serving clients domestically and internationally. We provide tailored solutions for both small and large-scale operations.Q: What is the process of ensuring quality and consistency for this product?

A: Our anti caking agents undergo strict quality checks for granule size, moisture content, and effective distribution. We implement consistent manufacturing practices to ensure each batch meets the required standards for both food and fertilizer uses.Q: How does the crystal shape of the anti caking agent enhance its performance?

A: Crystalline anti caking agents offer superior dispersion in powders, ensuring more uniform coverage and effective prevention of clumping. Their shape contributes to improved mixing and better long-term protection against moisture and friction.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cosmetic And Food Dyes Category

Acid Red 88 Dyes

Price 400 INR / Kilograms

Minimum Order Quantity : 10 Kilograms

Physical Form : Powder

Type : Other, Acid Red Dyes

Lipstick Colors Dyes

Price 1200.00 INR / Kilograms

Minimum Order Quantity : 10 Kilograms

Physical Form : Powder

Type : Other, Lipstick Colors Dyes

Usage : Other

Application : Other

Synthetic Food Colors

Price 800.00 INR / Kilograms

Minimum Order Quantity : 10 Kilograms

Physical Form : Other

Type : Other, Food Color

Usage : Food Dyestuffs

Application : Food

D And C Red -33

Price 4500.00 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Physical Form : Powder

Usage : Food Dyestuffs, Other

Application : Food

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free